Notes on Temperature measurement and sensors.

1. As of May 20,2019, the International System of Units (SI) was redefined and adopted.

In this adoption, all base units of measure (length, time, mass, electrical current, thermodynamic temperature, amount of substance, luminous intensity) have been defined by the seven natural constants (speed of light, Planck constant, elementary charge, Boltzmann constant, Avogadro constant, luminous efficacy constant and hyperfine transition frequency of Cesium). The International Temperature Scale (ITS-90) reflects the thermodynamic temperature scale, expressed in degrees Kelvin, by a series of reference points. Each point is a physical state of a material, such as hydrogen triple point (0K or -259.34C) and the freezing point of platinum (2042.15K or 1769.00C) .

2. In US, the organization responsible for all thermometry standards, research and calibration is NIST (National Institute of Standards & Technology). Its Thermodynamic metrology group maintains and develops national standards of temperature and supports of all types of contact thermometers calibration methods. https://www.nist.gov/pml/weights-and-measures/metric-si/si-units

3. There are two classes of temperature sensors: absolute and relative class. The absolute temperature sensors have a reference calibration point such as absolute zero on the thermodynamic scale, or any other reference point such as “ice water triple point”. Some examples of absolute sensors are RTDs and thermistors. An example of the relative sensor class are thermocouples. The thermocouple has to have a “reference junction” placed at a known temperature to measure the difference between the junction and the point of measurement. https://gerelectronics.com/usb-temperature-sensor/

4. A very large majority of all temperature sensors used in commerce and industry are thermocouples, RTD and thermistors.

5. All temperature sensors utilize a natural phenomenon that were discovered in the last few centuries and then studied and quantified scientifically. For example, in 1821, Thomas Johann Seebeck, accidentally observed that by joining wires of different metals end to end, there was a magnetic disturbance detected by his compass. This knowledge stayed unexplored until 1826 when A.C. Becquerel suggested that Seebeck’s effect could be used to measure temperature. It took another 60 years for the first thermocouple temperature sensor to be constructed by Henry LeChatelier.

6. Today the thermocouple temperature sensors are characterized by American Standards ANSI MC 96.1. https://blog.ansi.org/2018/10/thermocouples-calibration-table-ansi-mc961/

7. At about the same time, in 1887, Hugh Callendar published a paper describing how to use platinum as a temperature sensor. This platinum sensor was markedly different from the thermocouple as it utilized a physical property of platinum and other metals called thermo-resistivity. The thermo-resistive effect was first noted by Sir Humpry Davy in 1821. The RTD, as it is called nowadays, is an absolute sensor. https://gerelectronics.com/usb-temperature-sensor/

8. Thermistors have come to use in more recent times. It name is an abbreviation of “thermal resistor”. They are based on the same thermo-resistance effects discovered in the 1800’. However, they are not made of pure metals, but of metal oxides. Its temperature response (or transfer function) depends on its physical dimensions and the intrinsic resistivity of the metal oxide. After many years of experimental measurements, the relationship between the resistance and absolute temperature for a thermistor has been agreed to be a non-linear equation of the logarithm of thermistors resistance, R, and a polynomial equation of third order in temperature, T. For practical temperature measurements, because the equation is non-linear, the selection of the measurement range becomes of paramount importance. https://gerelectronics.com/usb-temperature-sensor/

9. In the following posts we will describe each of these devices in more details.

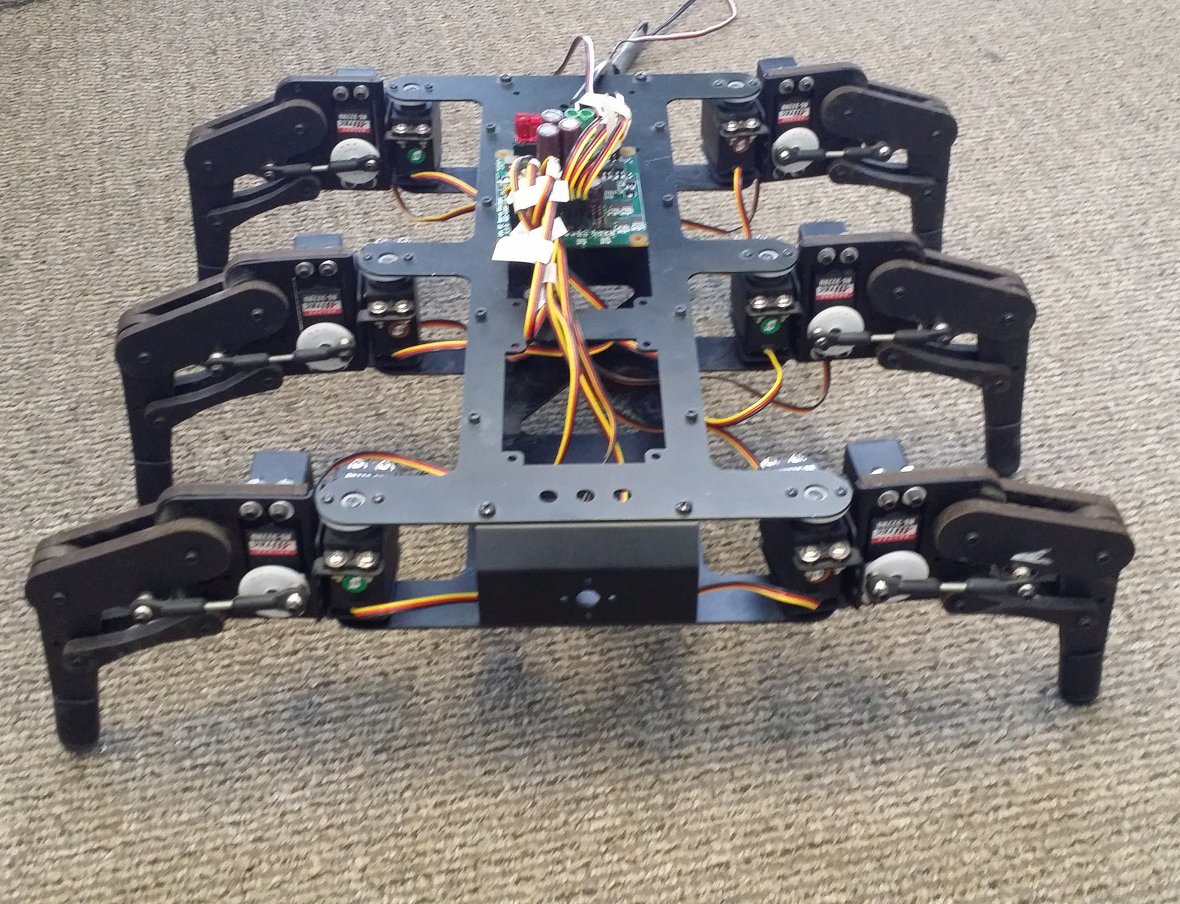

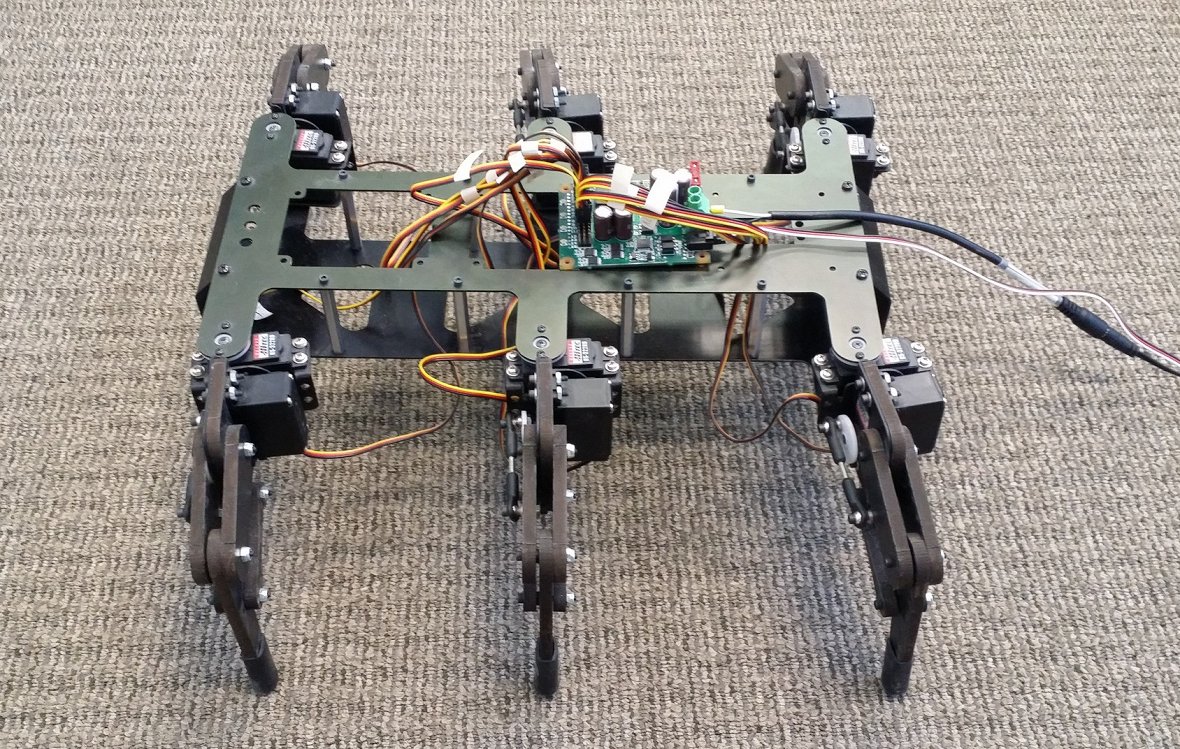

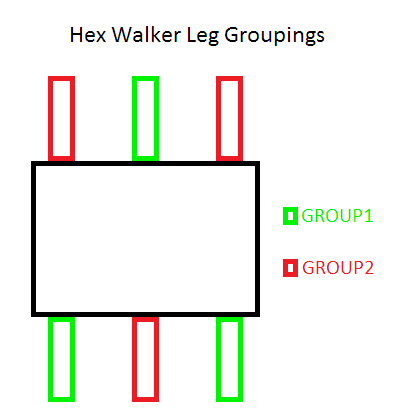

In order to turn, one tripod is lifted while the other set rotates in the given direction. To turn left, the right legs are moved forwards while the left legs are moved back, and vice-versa.

In order to turn, one tripod is lifted while the other set rotates in the given direction. To turn left, the right legs are moved forwards while the left legs are moved back, and vice-versa. For control from the joystick, these movements are combined to allow for more freedom of motion.

For control from the joystick, these movements are combined to allow for more freedom of motion.